Behind the Scenes of SILVA’s Cacao Lab

Why We Never Lose Our Temper When it Comes to Specialty Cacao Quality

The Silva Way

“Sourcing cacao with an identity while caring of Flavour, Forest, Farmers and the Future – that’s the ‘SILVA Way‘. Our mission and vision prompts a pivotal question: How do we distinguish beans of exceptional quality and exquisite flavour? The answer is very simple and unambiguous: Testing and tasting, testing and tasting, testing and tasting.

At our core, we are more than just a cacao importer; we are flavour connoisseurs, partner with local farmers and guardians of forests. Our journey begins with a unwavering commitment to sourcing the world’s finest cacao beans, embarking on a relentless pursuit that takes us to the furthest reaches of cacao’s origins.

At SILVA, we want to ensure that the cacao we source is of the highest quality, so that you can create the best chocolate. But then the question arises: how do we determine which beans are high quality or which cacao boasts great flavour?

What is Specialty Cacao?

The cacao market represents 5 million tonnes of cacao beans, with the bulk market being the behemoth of the cacao trade. Bulk or industrial cacao -which is produced in vast quantities and meets standardized quality parameters- is mostly only related to the physical assessment of the beans. In fact, more than 90% of the entire cacao market consists of bulk cacao. This market is closely linked to international market prices, and is often driven by cost considerations. Although this market is the backbone of the chocolate industry, it offers limited opportunities to add value for cacao producers, as the focus on quality rarely goes beyond a quick visual analysis.

For the record, we should start by pointing out that there is no industry-approved definition of what constitues specialty cacao. The International Cacao Organisation has a definition of fine-flavoured cacao, but for true specialty cacao we go a few steps further.

The specialty market represents the artisanal heart of the cacao trade and accounts for less than 5% of the market share. This market offers something exceptional: premium prices for cacao farmers processing smaller quantities of higher-quality cacao beans. What sets this market apart is an unwavering commitment to quality throughout the supply chain, from the selection and cultivation of cacao to the final beans.

To earn the prestigious ‘specialty cacao’ label, a rigorous evaluation takes place, covering both the physical properties and sensory qualities of the beans. These beans must be free of defects and display distinctive, positive aromas and flavours that result in a unique and complex flavour profile. The aim is to create chocolate that transcends the ordinary, offering a sensory journey unlike any other.

Specialty Cacao Identity | Beyond Taste, Traceability & Sustainability

Specialty cacao goes beyond taste; it embodies a set of values that are integral to its identity. It champions full traceability and ensures that the path from the cacao farm to your chocolate bar is transparent and ethical. Furthermore, specialty cacao embraces a deep commitment to farmer well-being and environmental stewardship.

In this world of chocolate -where cacao satisfies the masses- specialty cacao enchants those looking for a sensory adventure and a connection to the origins and identity of their chocolate. It is a niche market that celebrates craftsmanship, quality and sustainability, making it an essential and inspiring part of the global cacao landscape.

Work in Process

Flavour is undeniably one of the most important factors that make cacao ‘specialty cacao’. But how do we distinguish these cacao beans from the rest? The answer lies in a fascinating evaluation process.

The multifaceted evaluation Process

The road to identifying special cacao is far from simple, and it is a joint effort between farmers, experts and chocolatiers.

The core of the mission is threefold:

✔ unlock the inherent value of the cacao bean,

✔ define its different flavour characteristics,

✔ establish rock-solid traceability.

The Lack of a One-Size-Fits-All System

In the quest to quantify just how ‘special’ a cacao bean is, we encounter a fascinating challenge -there’s no universally accepted system. Instead, we find a rich tapestry of overlapping methodologies, all with their own insights and criteria. Some of the prominent evaluation frameworks include:

- International Standards for the Assessment of Cocoa Quality and Flavor (ISCQFS)

- Guidelines for the Sensory Evaluation of Cocoa Beans & Chocolate by Cocoa of Excellence (CoEx)

- Cacao Grading Protocol and Evaluation Sheet of the Fine Cacao and Chocolate Institute (FCCI)

- Federation of Cocoa Commerce’s Quality Assessment sets the industry standard for physical evaluation (FCC)

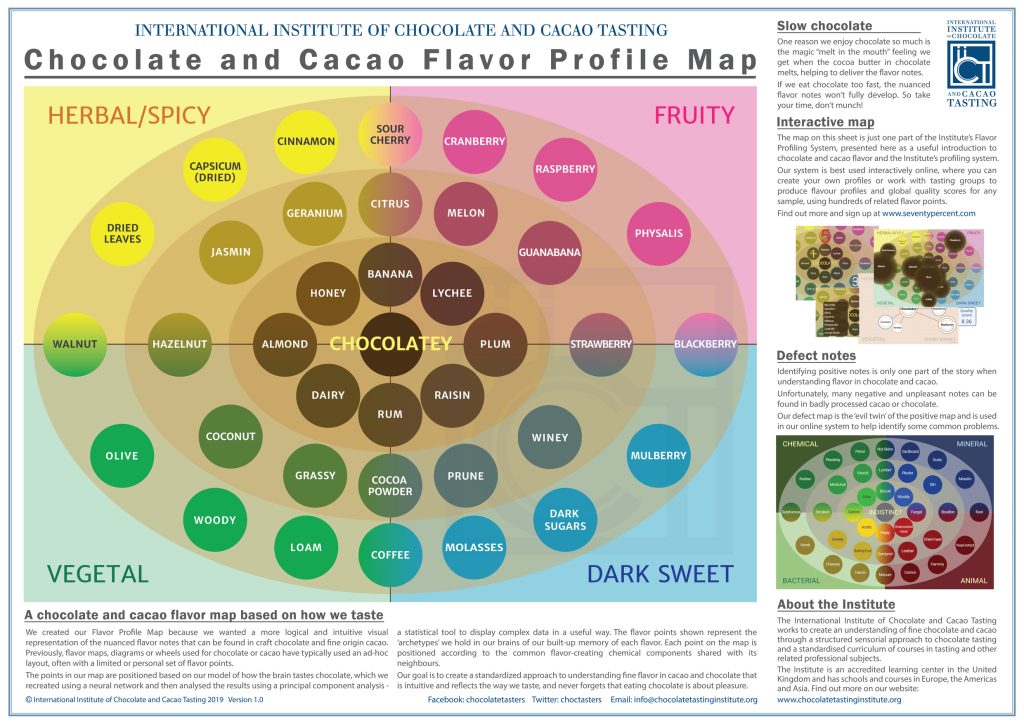

- International Institute of Chocolate Tasting (IICCT) & Taste With Colours provide tools for sensorial assessment

- Guide for the Assessment of Cacao Quality & Flavour (Cacao of Excellence & MOCCA)

Earlier this week, the ‘Guide for the Assessment of Cocoa Quality and Flavor’ was launched via a webinar with a Q&A session. Funded by the U.S. Department of Agriculture’s MOCCA project, this comprehensive guide provides detailed protocols and procedures for evaluating cacao as green beans, cacao liquor, and chocolate. These methodologies -developed by a diverse group of experts over several years- allow objective assessments of cacao quality and taste. Crucially, they are developing a universal language for describing cacao flavour properties, creating a common understanding among cacao professionals around the world.

While these systems sometimes differ in approach, they do share a common ground, and therein lies the beauty of our journey into specialty cacao. What follows is not a rigid set of tests, but rather Silva’s knowledge-driven approach that draws on the collective wisdom of these assessments. Besides the cacao standard, we are very inspired by the Specialty Coffee Association’s SCA protocol.

Finding Common Ground

Silva’s commitment to flavour excellence is not just for its own sake. It serves a crucial purpose: supporting cacao producers who are raising the bar and helping chocolate makers in their search for the perfect cacao bean.

Armed with this extensive knowledge, we are ready to advise and assist chocolate makers in making informed decisions about their choice of beans. Because ultimately, it is the collective spirit and cumulative expertise of all stakeholders that drive the journey towards specialty cacao

Testing, testing… One, two three

Finally, let’s start with the practical part of our cacao exploration, showing you ‘up-close’ how we at SILVA examine the physical characteristics and analyse the delicious aromas.

1. Physical Analysis

Aroma & Appearance

Our analysis starts with our sense of smell. We start with the beans’ unique aromas and carefully note down any odours that stand out, both good and bad. We then shift our attention to the appearance of the beans, checking for colour, external mould, uniformity and signs of unwanted guests.

Bean Count & Uniformity

Now we roll up our sleeves and ‘go quantitative’. We measure out exactly 100 grams of beans. We remove all defects (clamped, flat, etc.), so we can calculate the percentage of defects using a simple formula: (weight of all defects / 100 g) x 100.

On a defect-free sample of 100 grams, we then count their average size and weight. Repeating the average 3 times results in counting the beans. The uniformity of the beans is checked visually and by the deviation between repetitions.

Internal Analysis : Cut Test

- To further analyse the beans, we need to take a look at the inside as well. The cut test involves slicing the beans, and we have two options: a guillotine or manual cutting with a cutter. At SILVA, we opt for the hands-on approach with the cutter, since manual cutting ensures a smooth and precise result. Each bean undergoes a lengthwise cut, and we display the two halves side by side for a closer look. During this phase, our attention is drawn to three key factors:

- Defects : defective beans e.g. mold, insect damage, etc

- Colour grading: grades from gray to purple to brown, or white to light brown indicate development during fermentation.

- Fissuring: Fissuring -characterised by large splits or breaks in the bean’s internal structure- occurs due to proteolysis during fermentation and persists during drying. Beans with extensive fissuring are usually more fermented than those that look cheesy or slate-like when cut.

Fissuring and colour changes are different results of fermentation and do not always correspond; they are influenced by the bean’s genetics and the fermentation and drying process. Assessing both colour and fissuring rate provides a comprehensive evaluation. Slate-like beans can also result from harvesting pods that are not fully ripe.

Moisture

Now let’s talk about moisture content. Insufficient moisture, often due to excessive drying, leads to brittle and uneven beans. On the other hand, excess moisture poses a threat as it provides an ideal environment for mould growth. Mould not only affects chocolate flavour but also produces harmful mycotoxins such as ochratoxin A and aflatoxins.

The best place for cacao moisture is up to 8%, according to international standards. At SILVA, we aim for a moisture percentage between a maximum of 7% for hermetic storage bags and 7.5% for regular packaging. We rely on a handheld moisture meter to measure moisture content, ensuring accuracy by testing multiple samples of the whole batch. When things get really serious, we apply the ISO 2291 standard for measuring moisture using the dry mass method.

2. Sensory Analysis

Now that we have delved into the physical details of cacao evaluation, let’s explore the fascinating world of sensory analysis. In this phase, we bring the beans to life through flavour and aroma. We assess the potential presence of defect flavours, flavour potential, uniqueness and complexity.

Unroasted Cacao Bean Sensory Evaluation

Our sensory analysis starts with tasting the cut-test sample in order to assess possible off-notes. Metallic, cheesy, medicinal, tainted, etc are examples of off-notes. We then focus on discerning the prominent characteristics of cacao, namely astringency, bitterness, acidity and chocolate notes. These facets are evaluated on a scale of 0 to 10, allowing us to accurately quantify our sensory experiences.

After the basics, we move on to describe the flavour profiles. To guide us on this sensory journey, we use the ICCT flavour map, a valuable tool to characterise the nuances of cacao flavour. The map has a scientific backbone of flavour relationships and networks; it provides an intuitive framework and it is widely embraced by chocolate makers in the industry. This common ground ensures that we speak the same language when evaluating cacao.

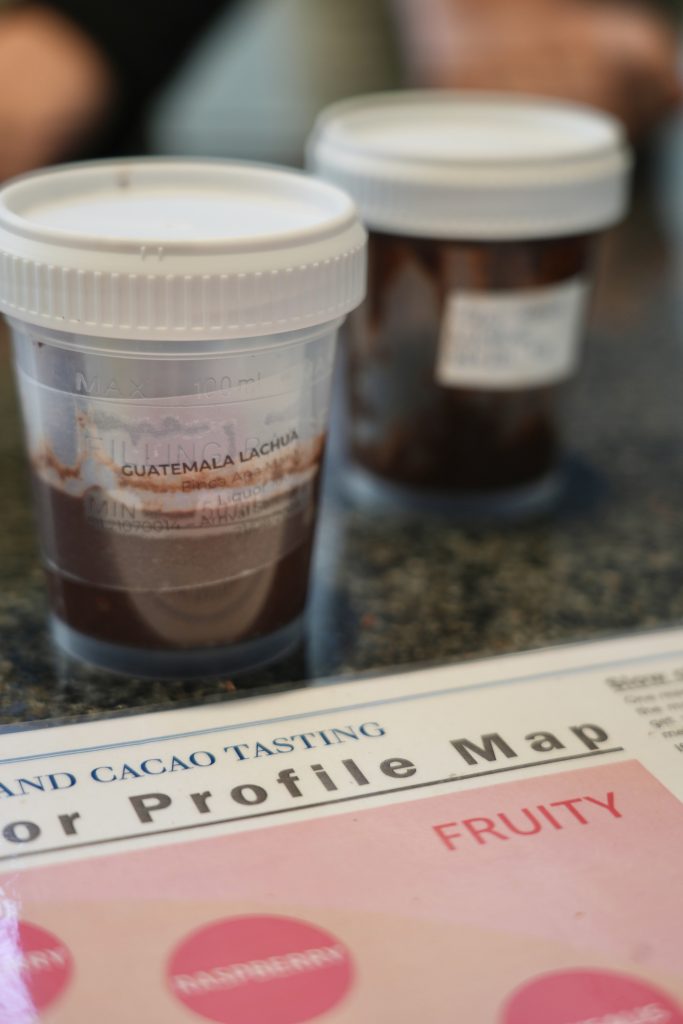

Cacao Liquor

In our eternal quest for flavour, we even make our own cacao liquor in our lab. This is also in the context of better understanding how the flavour of the bean can evolve during the chocolate process.

Based on the raw bean result, we determine an initial roasting profile; we crack the beans, winnow them, and do a short grind to make a 100% liquor. The liquor undergoes the same sensory evaluation. For new origins and samples, we play with different roasts to test and analyse how to fully unlock the flavour potential.

Chocolate

When we get intrigued by some liquors, we even go to the ‘bitter end’, playing around with some recipes with different sugar percentages. This way, we find out which beans are suitable for which purpose, and we can give our partner chocolate makers even better and more complete advice on choosing the right beans.

3. Staying Curious | Taking a pulse in similar sectors & fields | Beyond Cacao

In a world similar to that of specialty cacao -more specifically in specialty coffee- many established protocols are changing and innovating. Recently, the Specialty Coffee Association (SCA) unveiled the beta version of its quality protocol called “Coffee Value Assessment”, a new approach to assessing coffee that is generating much controversy in the industry. This new system promises not only to redefine the way we assess coffee, but also to have a significant impact on coffee producers, especially smallholder farmers.

What is at the root of this change? There is a recognition movement underway that coffee is not just a number on a scale, but a complex mix of origins, certifications and intrinsic qualities. Under this new assessment protocol, coffee professionals go deeper into the origin story and identity* of each coffee, paying attention to production methods, the producers behind the coffee and certifications such as organic or carbon neutral. This means that where the coffee comes from, and thus the values it embodies, now play a leading role in this assessment.

So what’s in it for the coffee producers? It’s all about adding value. The previous one-size-fits-all approach often meant that the nuances of a coffee’s taste were overlooked, affecting the price farmers received. With the Coffee Value Assessment, producers have the opportunity to highlight the uniqueness of their coffee, whether that’s the result of their sustainable farming practices or the specificity of their region.

Just as the coffee industry is evolving and starting to celebrate the diversity and origins of coffee beans -something we at SILVA have been doing since our very beginnings- the cacao industry is starting to embrace a similar approach. This gives cacao producers the opportunity to shine, enriching the cacao experience for consumers around the world. The winds of change are blowing through both sectors, promising a more exciting and equitable future.

The Testing Journey | Spilling the Beans Step by Step

We categorize our testing samples into various types, including experimental samples used during the design phase, type samples, pre-shipment samples, arrival samples, and re-evaluation samples. It is of utmost importance that these samples accurately represent the entire lot.

The evaluation process consists of a minimum of five meticulous steps::

> Step 1

Cut Test during Fermentation: The first step involves a cutting test conducted by the producers during the fermentation process. This initial assessment sets the foundation for the flavour journey and quality evaluation of the bean.

> Step 2

Physical & Sensory Test in the Field: In the second step, the cacao is subjected to the comprehensive physical and sensory examination to ensure it aligns with the type sample. This evaluation occurs in the field, either by our partner farmers or ourselves, after the drying process.

> Step 3

Pre-Shipment Physical & Sensory Test: The third step entails another rigorous physical and sensory examination of the sample before shipment. This critical pre-shipment evaluation is conducted by our team to guarantee consistent quality.

> Step 4

Arrival Physical & Sensory Test: Upon the sample’s arrival, we conduct yet another round of physical and sensory testing. Our team meticulously assesses the sample to confirm that it meets our high-quality standards.

> Step 5

Re-Evaluation after +6 Months: Even after the initial evaluations, we continue to monitor the cacao’s quality. For cacaos with larger storage time, we perform a re-evaluation through another round of physical and sensory tests to ensure that the flavour and characteristics remain excellent.

> Step 6

Additional Evaluation by Chocolate Maker: Additionally, it’s likely that the chocolate maker will conduct their own physical and sensory tests when they receive the cacao beans. This ensures that the cacao maintains its excellence throughout the entire production process.

Ranking the Cacao Stars

At SILVA, we stand for cacao with unique and consistent flavour profiles. Our cacao is traceable and produced with respect for farmers and forests. Based on the sensorial uniqueness & complexity, traceability, production size and physical quality assessment, we provide chocolate makers with the following product categories.

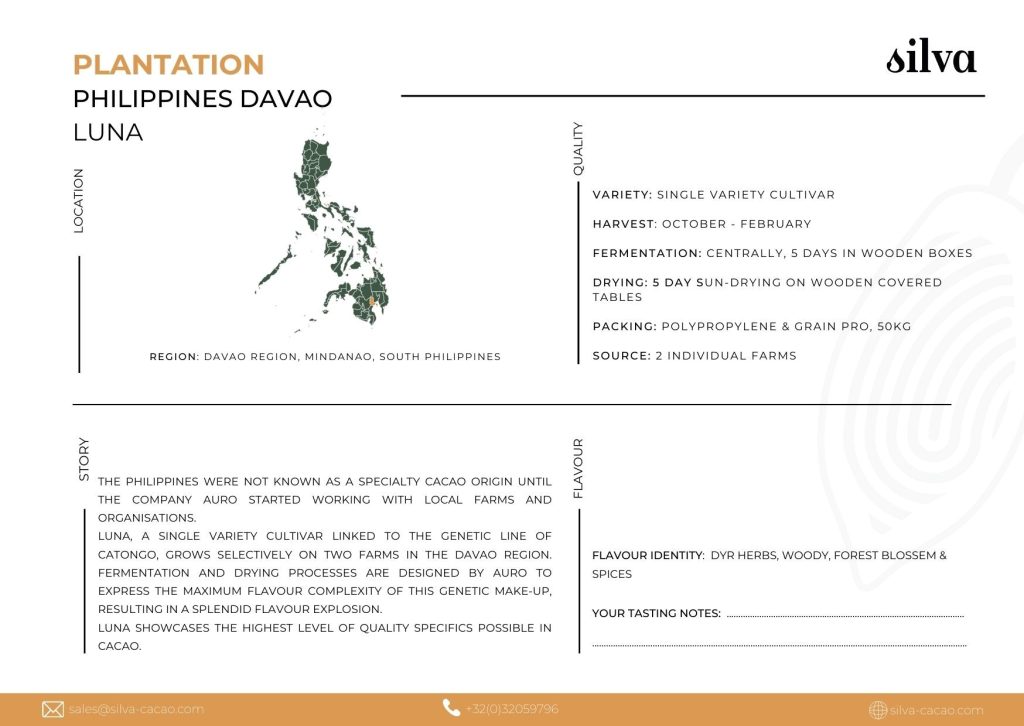

Plantation Cacao

✔ exceptional cacao with a unique sensory experience

✔ sourced from 1 single farm

✔ traceable up to farm level

✔ carefully physically selected

Special Selection

✔ exceptional cacao with a unique sensory experience

✔ sourced from a select group of farmers

✔ traceable up to farm level

✔ carefully physically selected

Exclusive lots & Limited Editions

✔ exceptional cacao with a unique sensory experience

✔ sourced from a select group of farmers

✔ traceable up to farm level

✔ carefully physically selected

✔ these category often involves specific genetics, distinct morphology or a particular post-harvest process

✔ limited availability

Regional Cacao

✔ signature cacao with a consistent flavour profile

✔ blended in 1 or more post-harvest centra

✔ traceable up to farm level

✔ while we don’t accept sensorial defects, physical defects (clamped, broken, flats,..) are accepted up to max 5%

✔ this cacao is a fine flavoured cacao, but does not meet the specialty cacao quality requirements

Conventional Cacao

It certainly happens that batches arrive with the goal of being specialty cacao, but we decided to de-classify them because of some (minor) imperfections. In this case, our goal is to find a good home for these beans, a good destination that miraculously turns out to fit their current assessed physical and sensory characteristics after all.

Ultimately, these ‘de-selected’ cacao beans have only minor imperfections and still meet basic standards for taste and quality.

It goes without saying that at SILVA we don’t like food waste, and all the more love Happy Endings…

Swipe Right for Quality | Cacao Bean Match Making 2.0

When making chocolate, the choice of cacao beans is crucial. It’s a bit like finding the perfect puzzle piece to complete the picture. Different chocolate projects require different cacao, each with its own characteristics and potential.

Some chocolate makers seek cacao beans with intricate flavour profiles, aiming to take their consumers on a sensory journey like no other. Others prefer beans that lead to delectable chocolates, perfect for a quick indulgence. Others are looking for cacao that is easy to work with, while still others enjoy the challenge of creating something unique and distinct.

The beauty lies in the diversity of cacao beans, and we at SILVA make it our mission to explore and evaluate them all. By carefully tasting and analysing each cacao bean, we want to help you find that ideal puzzle piece to complete your chocolate masterpiece. After all, there is a perfect bean for every chocolate maker’s creation.

Our Cacao Bean Facilities

Our cacao beans shuttle between different quality homes.

✔ SILVA’s Cacao Lab: Our home lab where we do all our testing. Fully equipped to test beans, taste beans, make liquors and chocolates and taste them too. Good vibes proof!

✔ Our sample storage, better known as our ‘the Cave of Ali Baba’ where we carefully track and store all samples of incoming batches

✔ SILVA’s specialty cacao is stored at Vollers Group’s specialised cacao warehouse in the Port of Antwerp, Belgium.

Cacao Quality Challenge

If you know SILVA a little, you probably also know that we don’t shy away from a nice challenge.

We love sharing our cacao knowledge, and there’s nothing we’d rather do than research which cacao would suit you best.

We are cacao matchmakers as well as cacao connoisseurs. All of our beans have a unique identity; we know their origins, their specific characteristics, their quality and their flavour profiles.

✔ Are you wondering which cacao bean quality would complement best your chocolate creation?

✔ Maybe you’d like to stop by our homelab to perform a few different cacao quality tests together?

✔ Or would you rather go on a (online) speed date with someone of our quality crew?

KUDO’S, CREDITS & INSPIRATION

SILVA Cacao |The Silva Way

SILVA Cacao | The Art of Cacao Sourcing

SILVA Cacao | Humidity in the Cacao Supply Chain I & II

SILVA Cacao | Making the Cut; testing cacao beans’ health and Fermentation

SILVA Cacao | Cacao Moth: don’t bug me please

SILVA Cacao | What is a Cacao Cut Test & When is it useful?

SILVA Cacao | Ruling the Roast

FCIA | FCIA Fine Chocolate Glossary

ICCO | Fine Flavour Cacao

CBI | The European market potential for specialty cocoa

ISCQF | International Standards for the Assessmrnt of Cacao Quality & Flavour

CoEx | Guidelines for the Sensory Evaluation of Cocoa Beans as Chocolate

FCCI | Grading Protocol and Evaluation Sheet

FCC | Quality Assessment sets the industry standard for physical evaluation

IICCT | International Institute of Chocolate Tasting and Taste With Colours provide tools for sensorial assessment

SCA | Protocols & Best

SCA | Beta Version of the Coffee Value Assessent Protocol and Forms

Equal Exchange and TCHO | Guide to the Cacao Sensory Analysis Tasting Form

Ferderation of Cocoa Commerce | Chocolate & Cocoa industry Quality Requirements