The Notion of Centralized versus Decentralized Fermentation

In our previous newsletter we talked about the importance of the fermentation process on flavor development. But it turns out that the vast majority of cocoa beans in the world are in fact not properly fermented. Once the cocoa is harvested, the wet beans tend to go bad quickly. Hence, it is extremely important that farmers take immediate action after harvesting. However, in many contexts this “action” is often without any structure or specific knowledge of the post-harvesting processing.

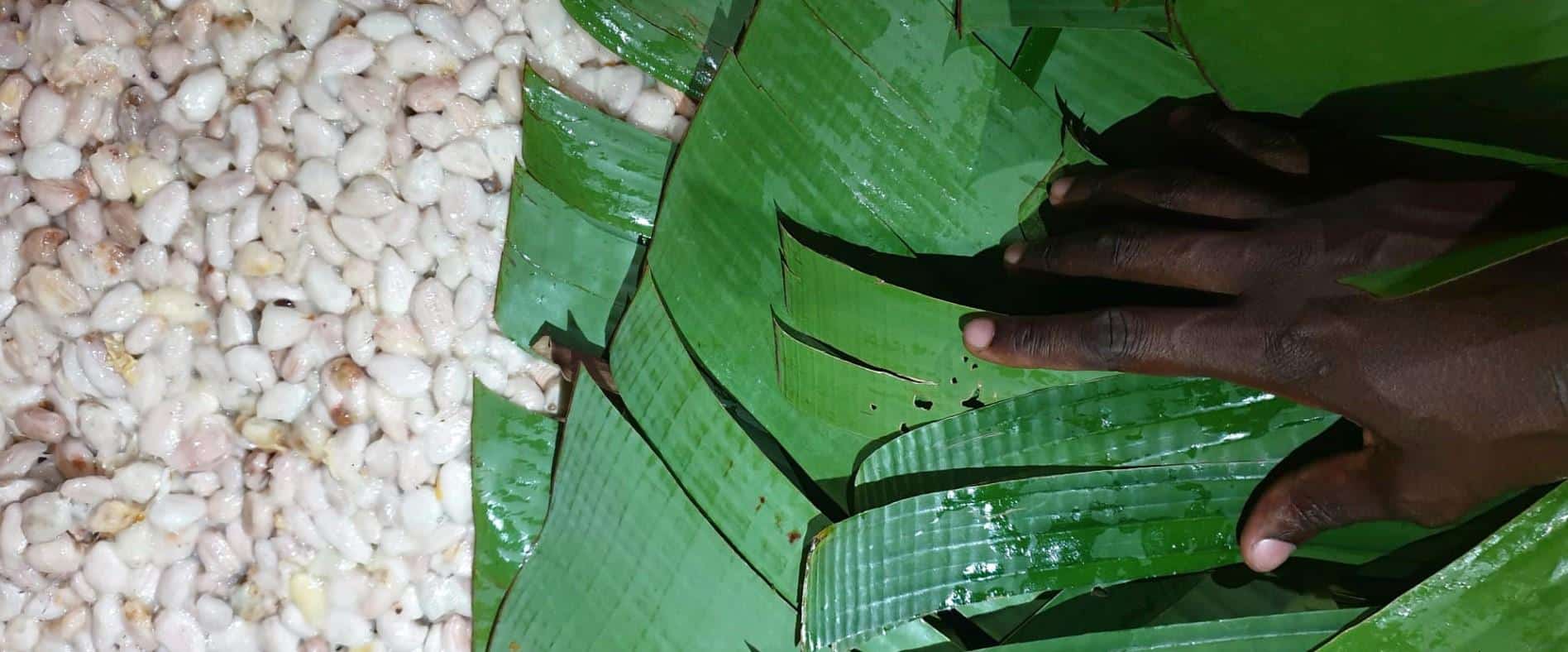

In regions where there is no market for wet mass purchase, no culture of proper fermentation or no notion of or focus on quality, farmers often prefer to quickly make a pile of the freshly collected wet cocoa beans on banana leaves on (or in) the ground and cover it with extra leaves. They will then leave this pile for some days so so the cacao pulp can break down and drain away, often without any additional practices. After this process, it becomes easier to dry the beans and sell them – regardless of the quality – to get some quick cash for the family. Probably about 90% of the beans are treated and sold in this way.

In countries where quality and specialty cocoa is more established already, farmers usually opt for volume accumulation using the box fermentation because it is easier to control quality in a centralized manner. Think about Brazil, Peru, Nicaragua, Guatemala, etc.

Today we want to look beyond the stereotypes that are often associated with box and heap fermentation and show why this is not a black and white story!

The Misconception of Decentralized Fermentation

Many people hold the assumption that decentralized fermentation can never lead to good quality cacao. The image often associated with heap fermentation is a dirty pile of cocoa between running chickens, garbage, and so on. Such process often results in beans that are very heterogenous in color ranging from pale to black on the outside and over- and under-fermented beans on the inside. But luckily not all assumptions are correct and we have some real-life cases that have proven that this image is not always correct!

Believe it or not, but excellent cocoa can come from either box or heap fermentation! The real importance lies in the fresh cacao selection, as well as its harvest and post-harvest process control. As soon as farmers understand which parameters are important during the process, they will be able to produce an excellent quality from both heaps and boxes. So it’s all about aligning the quality standards, training and understanding. Farmers need to understand that special care of their beans will lead to a better end result. They must be taught to work cleanly, monitor the temperature of the pile of cocoa beans, mix the mass evenly, add oxygen to the pile at key times and change the banana leaves regularly. And last but not least, they need to eventually stop the fermentation at the right time so as not to over-ferment and continue with a proper and clean drying process.

Zoi, cacao post-harvest expert from ZOTO, with whom we regularly work together, emphasizes that heap fermentation can lead to an equally good quality as box fermentation. She states that independent of fermentation method, there are two crucial parameters: vigorousity and technique of mixing as well as the cocoa bean pH changes. Farmers that use box fermentation often underestimate the effort needed to properly mix the fermenting cocoa mass so they think that simple shuffeling of the beans from one box to another is sufficient. While with heap fermentation, if you give the farmers the right mindset and tools, you can achieve much better end results. The same story applies with the pH value. With both box and heap fermentation, farmers often use a standard fermentation protocol of (e.g. 6 days with a turn every 2 days). But you actually have to look beyond this and see how the process evolves based on the pH value and Temperature of the beans, next to the physical changes (color, smell, etc).

Ultimately, it’s about getting farmers trained and dedicated. You can compare it with going to the gym. You can have the most amazing gym and equipment but as long as you don’t have the dedication and put in hard work you will never see the results you want!

The Excitement and Challenges on Centralized and Decentralized Fermentation

It goes without saying that a central post-harvest unit brings many advantages. A centrally-controlled unit has the same team that will always control the process from the reception of the wet mass of cacao until the final drying and selection of cacao beans. Having the processing in one place also helps to closely monitor the evolution of fermentation and drying. When the center is organized properly each production lot will get a number and traceability code and every batch undergoes a quality check. Ultimately only the best lots will be selected for the specialty markets. It speaks for itself that if the team is committed and qualified, and the post-harvest protocol is properly designed, this will lead to excellent and consistent cacao quality.

The downside is that such a set-up requires investment, training and close follow-up. For origins and regions with stable buyers who are willing to pay the price for quality, it‘s a perfect set-up. However, what we have already seen in many cases is that although there are excellent fermentation centers or major investments in infrastructure, it often appears to be a lack of knowledge to develop excellent qualities or no buyers willing to pay the correct price. So in order to make this model economically sustainable, what is needed is a link to the right markets.

On the contrary a decentralized fermentation process is much easier and cheaper to set-up. It requires proper training of individual farmers and technicians how to run the heaps and follow-up the evolution of the process. Committed farmers who understand how to manage their heaps, properly control the fermentation, mix at appropriate moments and stop the fermentation timely to start drying, can get excellent cacao qualities. The advantage is that the investment in infrastructure and follow-up is less costly than in a central set-up, so consequently farmers can get more of the added value created by excellent quality.

But of course, decentralized fermentation also poses challenges. One of the main difficulties is that heaps have limited volumes. Consequently, the heaps of different farmers will have to be consolidated/blended afterwards. So, in order to ultimately achieve consistent and excellent quality, it is imperative that, apart from applying the same post-harvesting protocol, the farmers are committed, attuned and understanding. An additional challenge that often arises is the availability of monitoring equipment. So is it possible to achieve great quality with decentralized fermentation? Yes it definitely is! But training, training, training and outstanding farmer commitment are key!

Uganda and Congo as Shining Examples of Controlled Heap Fermentation

Two of our most recent cacao origin projects are Uganda and Congo. For both origins we work partly with controlled heap fermentation, and for this we have collaborated with fermentation expert Zoi from ZOTO to achieve these amazing results. On the basis of training and providing the right tools, as well as guaranteeing the farmers’ commitment, we were able to achieve fantastic qualities and also make farmers experience themselves this new quality level at farm site!

About three years ago a project of the International Trade Center (ICT) was started in Uganda, called MARKUP. MARKUP has been working to promote specialty cocoa in Uganda, improve product quality, train farmers, find new markets, and control quality at farm-level. As a result of this team-work, we now have 2 cacaos with controlled-heap fermentation: “Mwena” from Semuliki Cooperative Union and “Mukali” from Bwamba Cooperative Union. Mwena means ‘heap’ in Lubwisi, the local language of Bundibugyo region in western Uganda which is an appropriate name for this cacao, since it is fermented in heaps on the farmer’s homestead. And our Mukali cacao is exclusively produced by women farmers! Who runs the world, Girls! All farmers have received fermentation training and close supervision by the agronomists of the Unions, so that they can control the fermentation process in banana leaves, & follow the prescribed protocols in a dynamic way.

Zoi: “I am so proud of the Uganda project. We made huge progress in a short time, and I believe it was an eye-opener for many chocolate makers who had previously the wrong perception and ultimately prefer the heap-fermented cacao over the box. Heaps can lead to great result as long as farmers are committed!”

Congo is a project very close to our heart, that we started in 2020 with different partners as a PPP (or Public Private Partnerships Project). Before our project, in the Ituri region, it was standard that all cacao was sold directly for the bulk market. With our project partners, we jointly developed two value chains with a diversity of flavor profiles. In addition to four specialty qualities that are fermented centrally, we are very happy to present a beautiful cacao from UPCCO cooperative “Okapi Signature”. The Okapi Signature cocoa grows in East-Congo, bordering the Okapi national park. Here again, it has been very important to train the farmers and provide them the tools to steer the post-harvest process in the right direction. The farmers all use the same fermentation and drying protocol and apply this to their controlled heaps in order to achieve a consistent and pleasant quality!